What are the differences between explosion-proof conductive slip rings and ordinary conductive slip rings?

Explosion-proof slip rings, also known as explosion-proof conductive slip rings, explosion-proof current collectors, explosion-proof collecting rings, or flameproof slip rings, are highly safe and reliable conductive components. They are designed for operation in hazardous environments with explosion risks, such as petroleum drilling platforms, chemical plants, military equipment, coal mines, and other settings prone to combustion or explosion.

The primary distinction between explosion-proof conductive slip rings and ordinary ones lies in their differing design objectives. Ordinary conductive slip rings focus on ensuring stable transmission of signals and currents during equipment rotation, requiring only basic electrical performance and mechanical reliability without specialized protective designs for extreme environments. In contrast, explosion-proof conductive slip rings prioritize adaptation to flammable and explosive environments. Beyond their core transmission function, they must eliminate potential hazards during operation through optimized structures and materials, ensuring safe use in dangerous scenarios.

Their structural designs and material selections also differ significantly. Ordinary conductive slip rings feature simple structures, using conventional metal contacts and insulating materials. Their sealing is merely for dust and moisture resistance, with no need to withstand extreme conditions. Explosion-proof slip rings, however, require more complex structures—such as highly sealed enclosures—and their internal conductive components and insulating materials must be heat-resistant, wear-resistant, and non-sparking. Some components even incorporate buffering or isolation structures to prevent dangers caused by friction or collisions.

Application scenarios represent one of the most notable differences. Ordinary conductive slip rings are used in equipment with no special safety requirements, such as common rotating machinery and automation devices in daily industrial settings, where there are no flammable or explosive substances and protection ratings are low. Explosion-proof slip rings, by contrast, are deployed in environments with flammable gases, dust, or vapors—such as chemical equipment, mining machinery, and oil-gas extraction devices—where strict safety standards mandate the use of slip rings compliant with specific explosion-proof ratings.

Differences also extend to safety certifications and testing standards. Ordinary conductive slip rings undergo routine testing for electrical parameters, service life, and operational stability, with no requirement for specialized explosion-proof certification. Explosion-proof slip rings, however, must pass professional explosion-proof performance tests, comply with specific standards, and obtain certification. These tests rigorously verify safety metrics such as sealing performance, spark resistance, and heat resistance.

Maintenance and usage requirements further diverge. Ordinary conductive slip rings demand minimal maintenance—regular cleaning and inspection of contact wear—without special environmental constraints. Explosion-proof slip rings, though, require stricter maintenance: their explosion-proof structures must remain undamaged, replacement parts must use identical explosion-proof models, and post-maintenance re-verification of explosion-proof performance is mandatory to prevent protective failure.

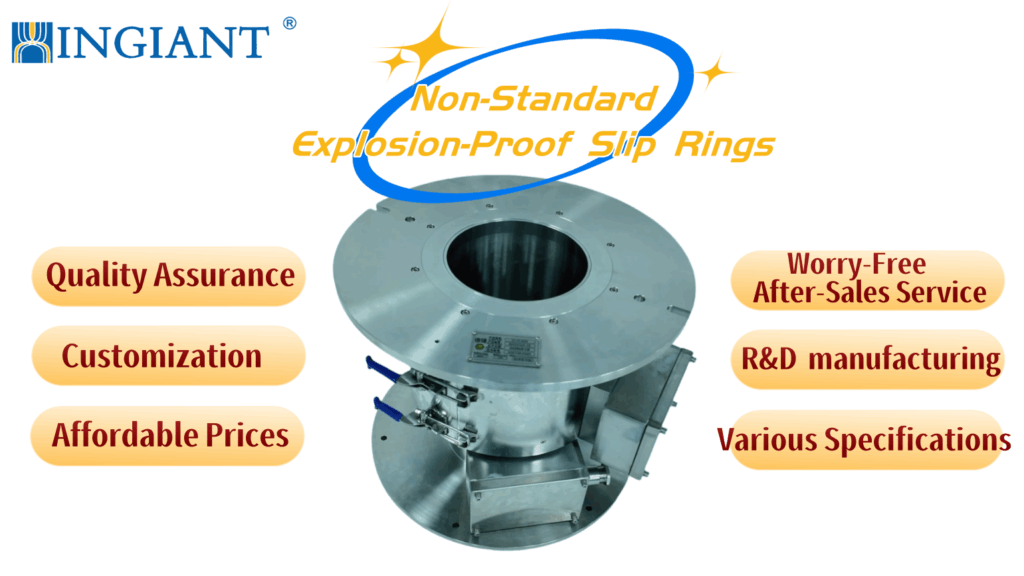

Due to inconsistent explosion-proof rating requirements, explosion-proof slip rings currently remain in the stage of non-standard customization. When selecting an explosion-proof slip ring, customers must provide parameters such as the required explosion-proof rating, number of channels, and electrical performance, allowing manufacturers to design and recommend suitable solutions. Explosion-proof slip rings manufactured by Ingiant Technology have passed explosion-proof certification, strictly complying with the national standard GB3836. Leveraging cutting-edge technology, they build a robust safety barrier to safeguard the operation of equipment in high-risk industries.