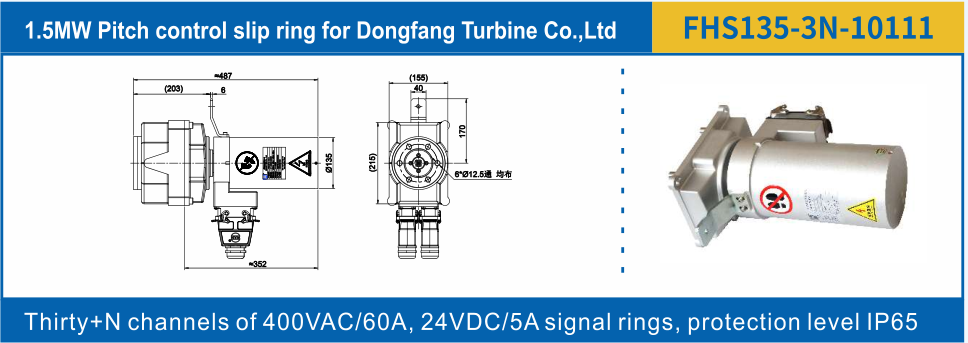

Why Choose Us

As manufacturer of various types of slip ring, Ingiant devoted to a combination of targeted design processes, a selection of the best raw materials, professional production conditions, 100% quality control and professional assembly at the customer’s site.

- Patent:27 kinds of technical patents of slip rings and rotary joints(include 26 untility model patents, 1 invention patent.)

- Experience: Provide OEM and ODM service, over 20 years of industry-related industry experience.

- Certificate:ISO 9001, GJB9001C, GB/T 19001-2008/ISO 9001: 2008.

- Warranty:The goods are guaranteed for 12 months from date of sale,under guaranteed time non human damage, free maintenance or replacement for quality problems arising from the products.

- Technical Support: Provide technical information and technical training support on a regular basis.

- Customization: Ingiant offer customization options to meet unique and specific requirements. We work closely with customers to design and manufacture slip rings that are tailored to their exact needs.

- Efficiency and Cost-Effectiveness: Ingiant are equipped with state-of-the-art machinery and production lines that enable efficient and cost-effective manufacturing processes.

- Quality Control: We have sophisticated testing equipment and procedures to verify the performance and durability of the slip rings before they are delivered to customers.