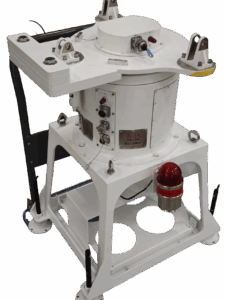

In modern fields like photography, videography, surveillance, and industrial inspection, Pan-Tilt Units (PTUs) play a vital role. They provide equipment with the capability for horizontal rotation (Pan) and vertical tilt (Tilt), significantly expanding the field of view and flexibility. However, achieving continuous, unlimited rotation while stably and reliably transmitting power, signals, and data requires a core component: the Pan-Tilt Slip Ring.

1: What is a Pan-Tilt Slip Ring?

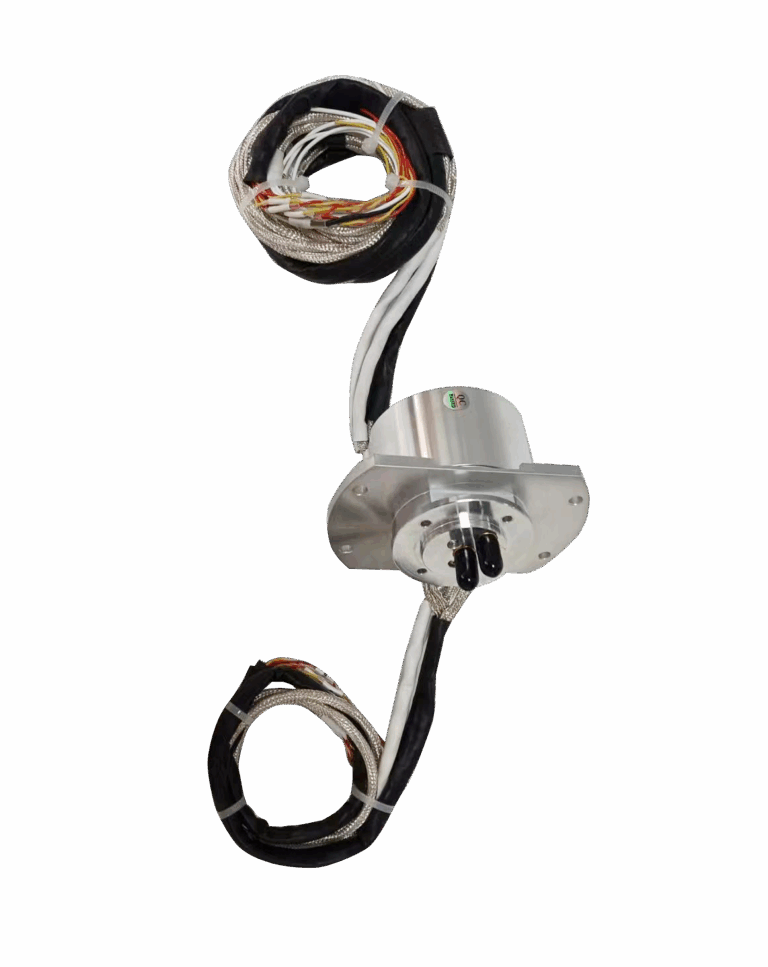

A Pan-Tilt Slip Ring, also known as a rotary electrical slip ring, rotary electrical joint, or rotary connector, is a precision electromechanical device. Its core function is to solve the problem of continuous, non-twisting transmission of power, signals (including video, control, network, sensor signals, etc.), and/or fluid media (such as gases or liquids) between rotating components and stationary components.

- •Basic Structure:

- •Rotor: Fixed to the rotating part of the PTU (typically the rotating platform or camera mount) and rotates with the PTU. The rotor has conductive ring paths or fluid channels.

- •Stator: Connected to the stationary base of the PTU. The stator has corresponding contact brushes (or electrical contacts) or fluid seal interfaces.

- •Contact Interface: As the rotor spins, its ring paths maintain sliding contact with the stator’s contact brushes/points, establishing an electrical pathway. Fluid channels transmit media through precision rotary seals.

2: Key Functions and Value of Pan-Tilt Slip Rings

- Enable Unlimited 360° Continuous Rotation: This is the fundamental value of slip rings. Without one, PTU rotation is limited by cable twisting (typically to just a few turns). Slip rings allow infinite rotation, enabling applications like panoramic surveillance and continuous tracking.

- Ensure Stable Power and Signal Transmission: During rotation, slip rings must maintain uninterrupted power supply and stable transmission of various signals (especially HD video, high-speed data) with low loss and noise. High-quality slip rings minimize signal attenuation, interference, and packet loss.

- Simplify System Structure and Maintenance: Eliminates risks of cable twisting failures (e.g., cable breakage, connector loosening), enhancing system reliability, durability, and reducing maintenance needs.

- Support Complex Multi-Channel Transmission: Modern PTUs often integrate various devices like HD cameras, IR thermal imagers, laser rangefinders, sensors, and lighting. Slip rings can incorporate dozens or even hundreds of channels to simultaneously transmit power, video, control signals, network data, serial communications, etc.

3: Critical Technical Characteristics of Pan-Tilt Slip Rings

- 1.Transmission Performance:

- •Current/Voltage Capacity: Must meet the power requirements of PTU motors, heaters, illuminators, etc.

- •Signal Types & Bandwidth: Support for interfaces like HDMI, SDI, USB, Ethernet (Cat5e/Cat6), RS232/485, CAN bus, analog video, Gigabit Ethernet, and even fiber optic signals, meeting their bandwidth and latency demands.

- •Signal Integrity: Low insertion loss, low crosstalk, high shielding effectiveness to ensure HD video without snow/noise/ghosting and stable data communication.

- 2.Rotation Performance:

- •Rotation Speed: Must match the PTU’s maximum speed.

- •Lifespan: Usually measured in millions of rotations or years of service, dependent on brush/contact material, lubrication, sealing, and manufacturing quality.

- •Friction Torque: Low and stable friction torque is essential to avoid excessive load on PTU drive motors.

- 3.Reliability and Environmental Ruggedness:

- •Ingress Protection (IP Rating): High IP ratings (e.g., IP65, IP67) are crucial to resist dust, moisture, and even water ingress.

- •Environmental Resilience: Wide operating temperature range (e.g., -40°C to +85°C or higher), resistance to salt spray corrosion (essential for marine/coastal environments).

- •Vibration & Shock Resistance: Must perform reliably on mobile platforms (vehicles, vessels, aircraft) or in industrial vibration environments.

- •Low/Zero Maintenance: High-quality designs aim for long life and minimal or zero maintenance.

4: Primary Application Scenarios for Pan-Tilt Slip Rings

- •Security & Surveillance: Dome cameras, high-speed PTZ cameras, panoramic cameras.

- •Film & Broadcast: Cinematic robotic camera heads, drone gimbals, specialized filming rigs.

- •Industrial Inspection: Machine vision systems, automated inspection platforms, rotary scanning equipment.

- •Aerospace: Aircraft electro-optical pods, satellite communication antennas.

- •Marine & Offshore: Vessel-mounted surveillance PTUs, radar platforms.

- •Research & Military: Telescope mounts, sighting systems, radar systems.

- •Robotics: Service/industrial robots with rotating joints requiring power/signal transfer

5: Key Considerations When Selecting a Pan-Tilt Slip Ring

- Channel Requirements: Clearly define the signals to be transmitted (types, number, bandwidth/speed) and power levels.

- Electrical Performance: Voltage, current, signal integrity needs (impedance matching, shielding, bandwidth).

- Mechanical Constraints: Physical size (diameter/length), weight limit, operating speed, required lifespan.

- Environmental Conditions: Operating temperature, humidity, necessary IP rating, vibration/shock levels.

- Reliability Needs: Is long life or zero maintenance critical?

- Cost Budget: Balance performance requirements with budget constraints.

6: Conclusion

Though small, the Pan-Tilt Slip Ring is an indispensable “lifeline” in modern high-performance PTU systems. It silently bridges the gap between rotation and stillness, ensuring the uninterrupted flow of power and information. As PTU applications evolve towards higher resolution, greater intelligence, and increased complexity, demands on slip ring bandwidth, stability, reliability, and integration intensity will continue to rise. Selecting a high-performance, reliable Pan-Tilt Slip Ring is a critical step in guaranteeing the smooth operation and optimal performance of the entire PTU system.