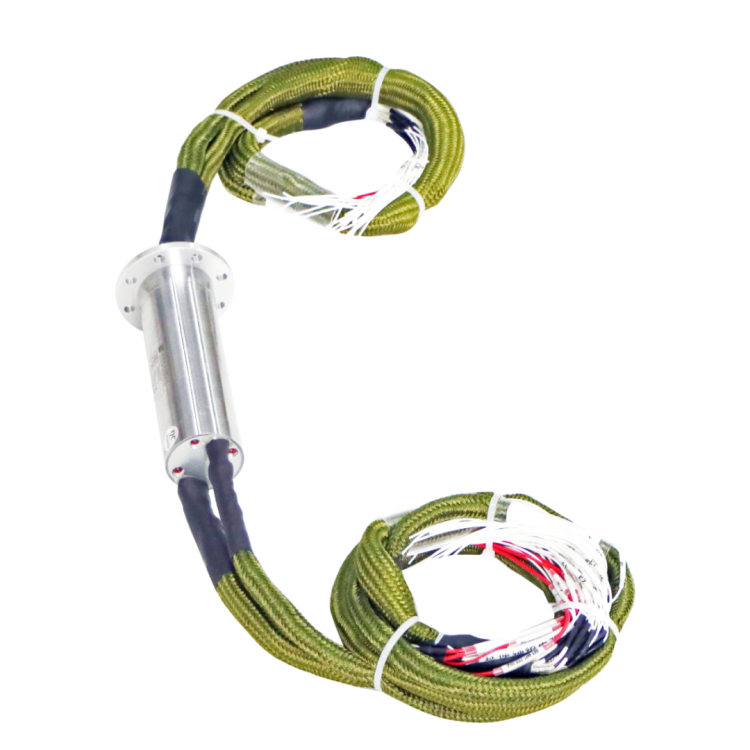

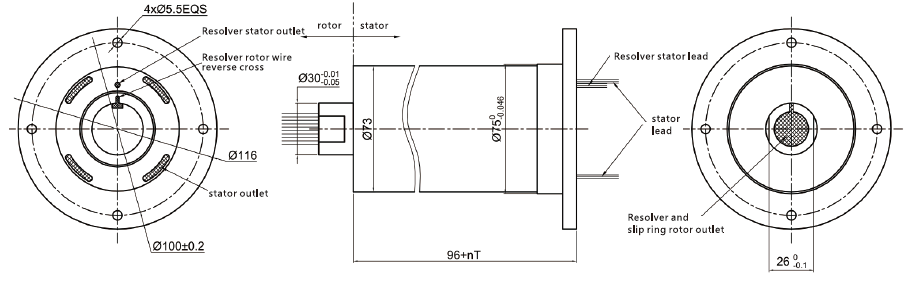

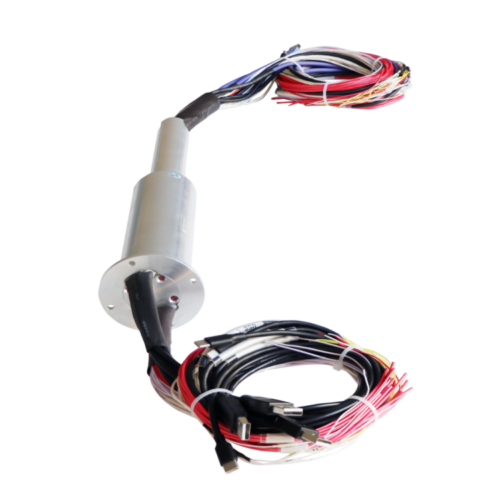

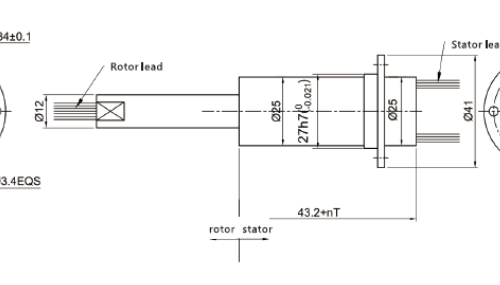

DHS032-37 High-quality encapsulated miniature slip rings for use in space-critical applications

Advantages of Capsulated Slip Rings

- The encapsulation protects the inner workings of the slip rings against the following disturbances, depending on the level of protection and enclosure material:

- Intrusion of dust

- Ingress of moisture

- Electrical interference

- Vibration

- Slip

- Shocks, blows and vibrations

Ingress of dust, especially electrically conductive metal or coal dust, will cause short circuits in a very short time. Since the contact rings and the sliding contacts are not insulated, they react extremely sensitively to penetrating dust. Non-conductive dust can settle on the rotating components and form an undesirable insulating layer.

Penetrating moisture can cause corrosion on the contacts. To ensure maximum operational safety, the contact rings and the sliding contacts are coated with silver. This metal only forms a thin oxidation layer, which immediately removes itself through normal operation of the slip ring. Alternatively, the surfaces can be provided with a gold alloy, which has a positive effect on signal transmission quality and prevention of oxidation.

Electrical disturbances penetrate less into the slip ring, but they can escape from it. Any slight loss of contact can cause an arc, which emits a radio signal. This radio signal can interfere with surrounding components, especially those with wireless signal transmission. The encapsulation prevents these disturbing emissions and shields them reliably.

Finally, the encapsulation is designed to be so robust that it is largely insensitive to mechanical stress. For particularly demanding environments, we also offer enclosures made of stainless steel. These are also ideal for hygienically critical environments. Stainless steel can be disinfected very well and has aseptic properties.