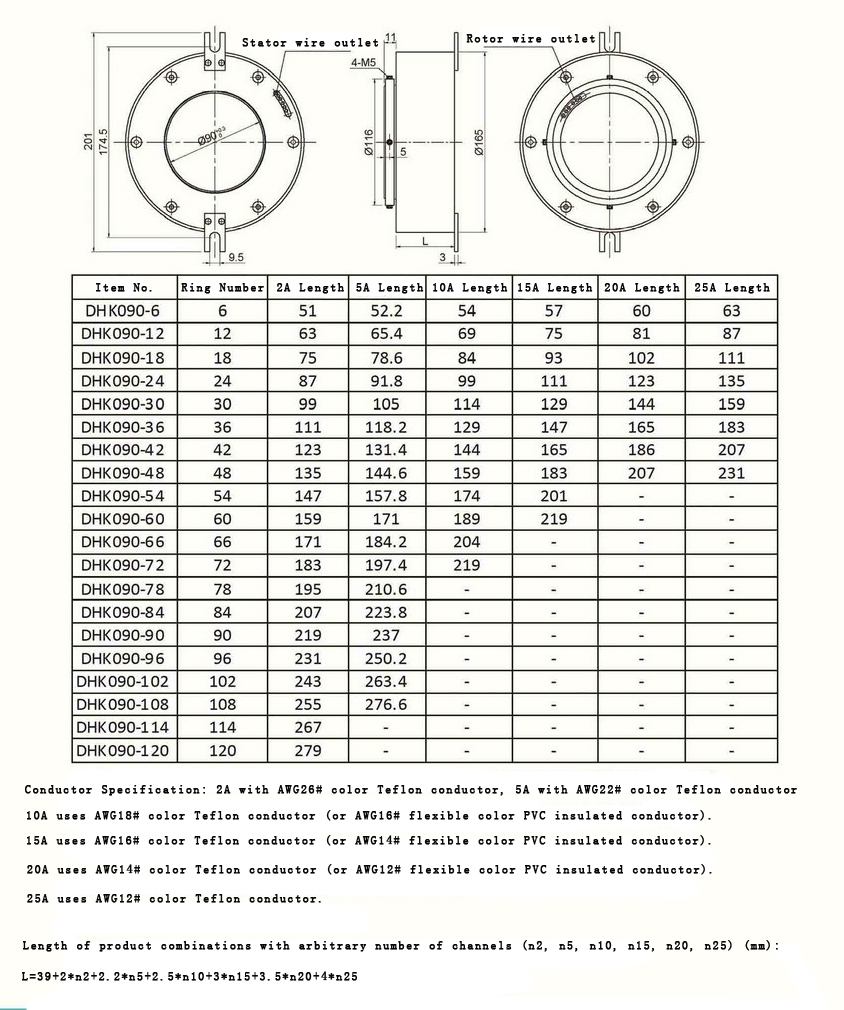

DHK090-100 standrad series hollow shaft slip rings 90mm 100 channels

Structure of the hollow shaft slip rings

A hollow shaft slip ring, like any component of this type, consists of two sleeves that are rotatably inserted into each other. The inner sleeve is hollow so that it can be fitted onto a round profile. At the inner edge, the inner sleeve has at least one screw for a non-positive or positive connection with the profile that has been passed through.

In addition, they have a small flanged holder on the outer ring. With the help of a groove or a screw, this can ensure that the outer sleeve does not rotate. The inner and outer sleeves are free to rotate, but have a very firm connection along the longitudinal axis.

This ensures that contact between the slip rings and the brushes is always secure. Wiring harnesses are soldered to each of the inner and outer contacts. They retain their colour so that confusion during assembly is impossible. The contact between brush and slip ring is maintained by an integrated spring. This prevents the current or signal transmission from breaking off even at high speeds. Hollow shaft slip rings are encapsulated. On request, they are available in waterproof or particularly impact-resistant versions.